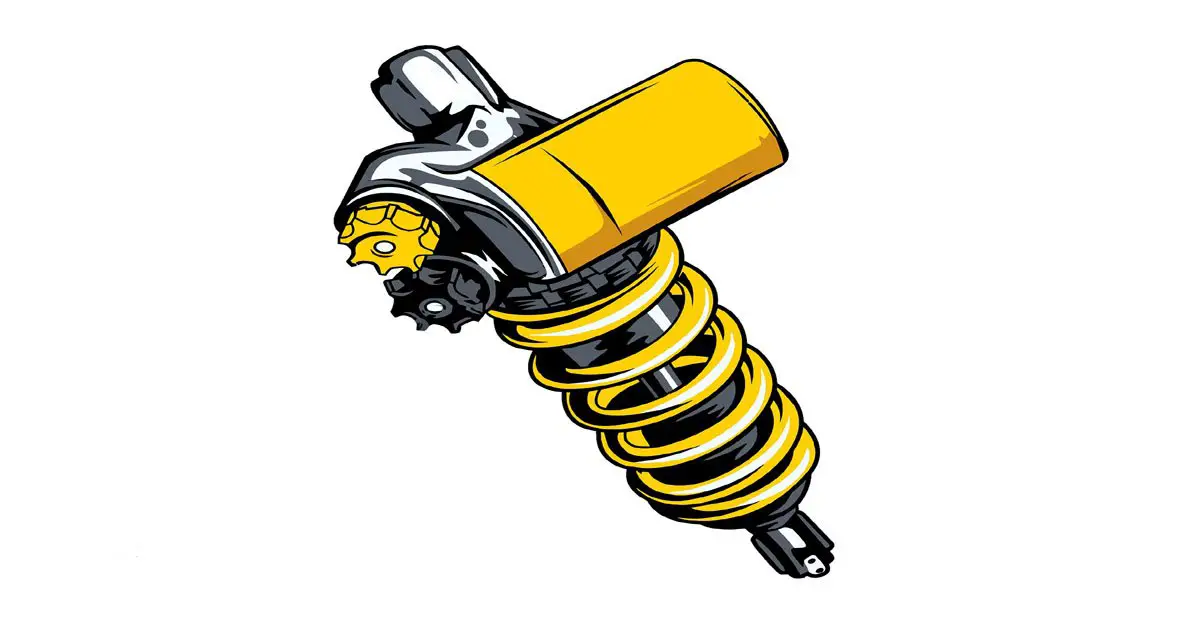

You should know by now, The cars you drive are not only made with an engine, body, and wheels. There are many different parts also remaining like shocks or shock absorbers, which are versatile of your car parts responsible to maintain a comfortable ride. The key role shock absorbers play is to reduce vibration and bump and stay connected with road surfaces to ensure a smooth ride. By doing this, it increases the braking and handling ability of drivers. Now this time, many types of shock absorbers offering for your cars to adjust to different road conditions.

Types of Shock Absorber

There are three main types of shock for different vehicles to serve different purposes.

1. Conventional telescopic shock absorbers

It is the most common shock absorber out of these three. This shock does the same job as does the other two. It is a most common shock for, it is made stronger to cope up with heavy-load and forces. Inside, hydraulic fluid, which allows mechanical energy from driving over the road smoothly. This type of shock absorber has evolved into acceleration sensitive and gas-charged, twin-tube are included with this component.

- Twin-Tube– outside it looks similar to a monotube, but inside, twin-tube comes with a second cylinder for internal fluid. This design is most commonly found in cars and smaller SUVs.

2. Strut type of shock absorbers

Here, it comes with monotube shocks, and the monotube comes with a pressure tube. Regardless, this type of shock comes with two pistons, a floating piston & a working piston. These components help to stay on a grip when cars go on the rough road.

- Mono-Tube– it comes with the simplest design that requires use in heavy-loaded vehicles. Literally, this design is expensive rather than a twin-tube design. Monotube shocks are commonly found in Trucks, Van & Jeep, and perfectly go with tough road conditions.

3. Spool valve

Lastly, the spool valve is completely compared with the monotube, twin-tube, and piston-sensitive mechanism. It is composed of oil passages within a cylindrical ladle. This is also used as an electrical control.

- Electrical controls– it is controlled by s switch via a cars` computer system. Electronic shock, which has an iron-containing hydraulic fluid most commonly known as ferrofluid. Other electronic shocks are controlled by electronics known as solenoids. This shock is commonly found in GM vehicles.

How Do Shock Absorbers Work?

Basically, a Shock Absorber is a cushion to your vehicle on a bumpy ride. It provides the control and stability your car needs when it’s moving on an uneven surface. So how does it do that? Let’s get to the physics of this!

When spring is disturbed by an amount of force it keeps on oscillating back and forth until its entire energy has been spent. We can compare its motion to a curve that keeps going on and on for an indefinite period of time, as long as the energy persists.

This is how your car would keep oscillating whenever it would hit an uneven surface. But that’s not what you call a smooth ride! Can you imagine how uncomfortable that would be? And this is where the Shock Absorbers come into action. They dampen the continuous oscillations of the spring by converting the kinetic energy of the Shock vibrations into other forms of energy. Say, heat energy which heats up the hydraulic fluid or hot air which is expelled outside or any other form of energy that can be used or stored later. Thus the oscillating spring comes to a halt and your car gains its stability right after it hits a bump.

Just when the curve touches the baseline, your vehicle stops oscillating and there you have your smooth ride back on track.

The conventional telescopic Shock Absorbers are either Twin-tubes or Mono-tubes. The basic structure of a Twin tube consists of two tubes – A Working Tube within A Reserve Tube. Both the tubes are filled with hydraulic fluid. There is a piston in it with valves at the bottom. So, when the vehicle hits a bump on a road, the piston moves up and down. With this, the hydraulic fluid also moves from one chamber to the other through the valves and ‘holes’ in the piston. At the same time, the energy of shock vibrations from the bump is converted into heat energy which heats up this fluid, and the energy is thus dissipated. So the vehicle stops oscillating. And there you have your smooth ride!

See also